| Length |

| 6.77 metres |

| Wide |

| 0.79 metres |

| Height |

| 1.08 metres |

| Weight |

| 2,200 kilograms |

| Propulsion |

| 7.5 hp direct current motor |

| Armour |

| – |

| Armament |

- Standard Warhead, 400 kilograms

- Medium Warhead, 300 kilograms

- Short Dual Warhead, 180 kilograms

| History |

|

The operational use and training with the Siluro a Lenta Corsa during wartime revealed significant limitations in the craft’s design. Despite advancements in materials and technology since the inception of the first self-propelled underwater craft in 1935, it became evident by 1942 that a complete redesign was necessary rather than further refining the existing model.

In January 1943, the task of developing a new craft was assigned to engineer Major Mario Masciulli, working alongside Captain Travaglini, who managed the secret workshop aboard the Olterra. Engineer Guido Cattaneo from CABI, Milan, also contributed to the project, guided by specifications from the X Flotilla Mas Headquarters. The project gained urgency after the failures experienced during the July 1942 operations at Alexandria and Gibraltar.

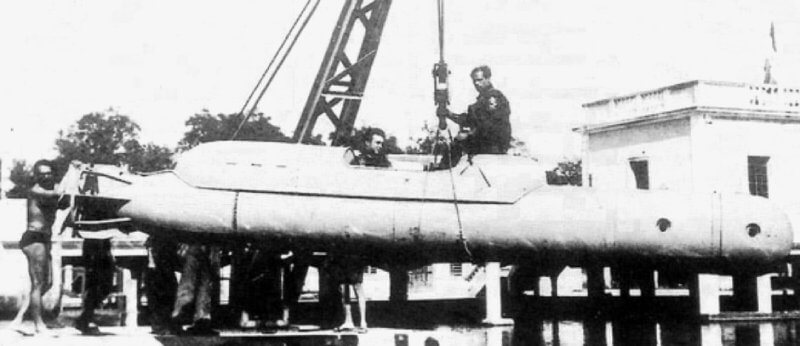

Supervised by the Underwater Weapons Command at the La Spezia Dockyard, the San Bartolomeo Torpedo Workshop began producing the prototype of this new self-propelled craft in February 1943. The craft was officially designated as the Siluro San Bartolomeo (SSB), referred to as the Delta type in the records of the Caproni company, which was the primary contractor for mass production. By March 1943, work was progressing rapidly to ensure operational readiness.

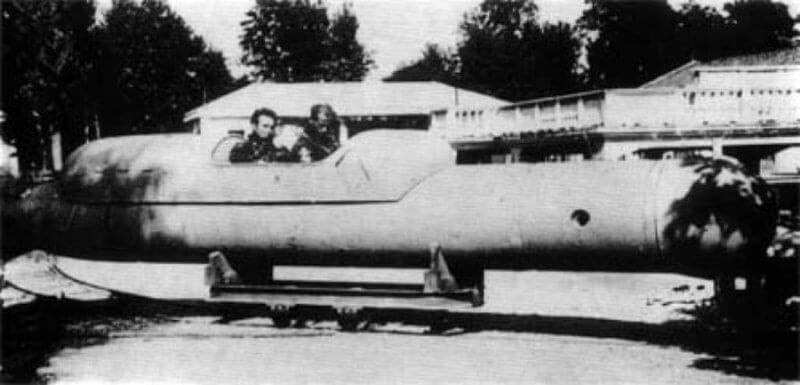

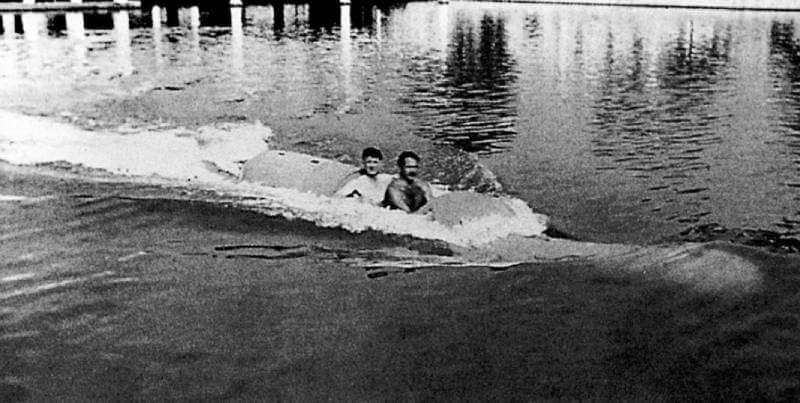

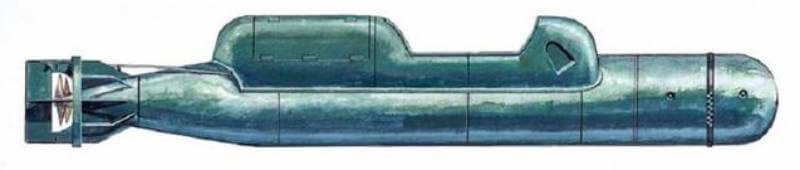

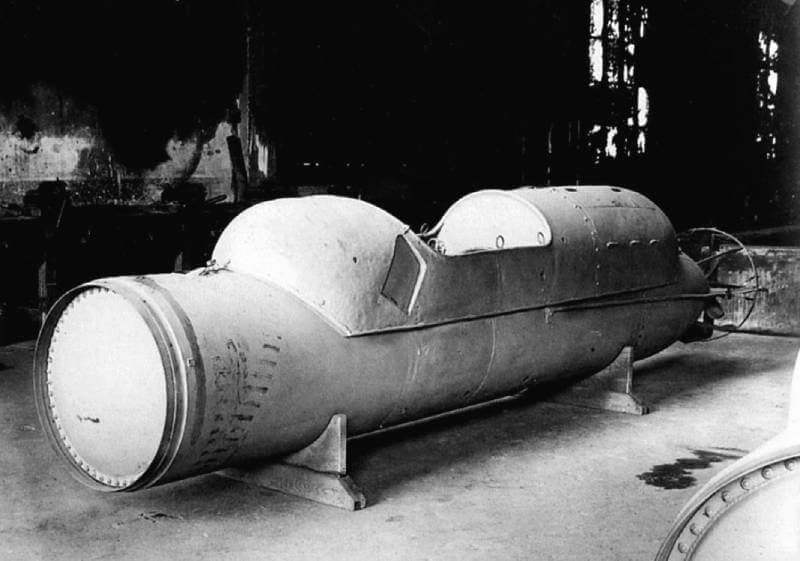

By April 1943, the construction of the Siluro San Bartolomeo prototype had progressed, with initial sea trials conducted in late May of that year off the coast of La Spezia. The results were generally positive but indicated minor adjustments were required, delaying further production until July 1943. The SSB followed the conceptual design of the Siluro a Lenta Corsa but featured notable differences. Although similar in length, the Siluro San Bartolomeo had a larger, bulkier frame due to the increased diameter of its main body (approximately 780 millimetres compared to the 533 millimetres of the Siluro a Lenta Corsa). The craft also featured an upper fairing that enclosed the cockpit, providing tandem seating for two operators inside the central section, rather than having them ride astride the craft.

This enclosed configuration offered greater protection for the operators, reducing the impact of water resistance at higher speeds, which reached 4 knots compared to the Siluro a Lenta Corsa’s 2.5 knots. This design allowed for extended surface travel, even in rougher conditions. The prototype weighed approximately 1,860 kilograms and could carry a standard warhead with a payload of around 400 kilograms.

The enhanced power output and battery capacity were key improvements, with the batteries divided between compartments at the front and rear of the operator seats. This configuration contributed to greater speed and improved range. The development of these enhanced power systems began in January 1943 and continued through to August, with refinements made during testing.

While the primary dimensions of the Siluro San Bartolomeo remained close to those of the Siluro a Lenta Corsa, ensuring compatibility with the watertight transport cylinders of existing submarines, certain innovations were introduced. Like earlier prototypes of the self-propelled Tesei craft, the Siluro San Bartolomeo employed two counter-rotating three-bladed propellers. Additionally, foldable horizontal fins were installed at the front to enhance depth stability.

Following successful trials of the prototype in June 1943, it is believed that two further pre-production units were commissioned at the San Bartolomeo Torpedo Workshop by July 1943, incorporating adjustments based on ongoing testing. By August 1943, these units were prepared for further trials in the Gulf of La Spezia.

The precise number of Siluro San Bartolomeo units ordered before the armistice in September 1943 remains unclear. However, construction commenced in mid-1943 at Caproni’s Taliedo factory in Milan. The hulls, manufactured by Gianazza Bros of Legnano (with eight produced by August 1943), were supplemented by warheads supplied by the Vulcano Company of Brescia. Production at Taliedo continued through the summer, with delays attributed to Allied bombing raids on Milan during July and August 1943.

By September 8th, 1943, when the armistice was announced, it appears that only three Siluro San Bartolomeo’s were completed – the prototype and two pre-production models, all built at La Spezia. One of these was designated for disassembly and covert shipment to Spain, where it was to be reassembled at the Olterra for an attack on Gibraltar scheduled for October 2nd, 1943. This operation was planned to coincide with the deployment of four MTR explosive boats transported to Algeciras by the submarine Murena.

Future models, tested by Caproni in late 1943, housed the trim pumps beneath the operator seats, reducing pipework and allowing easier access for maintenance.

By July 1944, Caproni had received orders for 16 additional units, with expected deliveries by November 1944. However, material shortages and production delays limited progress, and records of any Siluro San Bartolomeo deliveries to German forces remain inconclusive.

Despite plans for broader production, by the time the war ended in May 1945, only the initial three Siluro San Bartolomeo units were known to exist. Following the conflict, several incomplete Siluro San Bartolomeo’s were discovered at Caproni’s Taliedo facility, with four nearing 80% completion, another four at 50%, and four at 40% by the summer of 1944.

After the armistice and the war, both the British and United States navies are able acquire several of these units for evaluation. They conduct trials with the Siluro San Bartolomeo. One craft is transported to the United States, where it undergoes testing by the Office of Strategic Services (OSS), the precursor to the CIA, and the Underwater Demolition Teams (UDT), now known as the Navy SEAL’s.

This particular Siluro San Bartolomeo was later placed on display alongside the first nuclear submarine, U.S.S. Nautilus, at the Submarine Force Library and Museum in Groton, Connecticut. Exposed to the harsh Connecticut weather, the craft fell into disrepair, ultimately leading to its scrapping. The exact circumstances remain unclear, and it is unfortunate that the vessel was not transferred to another museum or preserved in storage.

Today, the remaining Siluro San Bartolomeo’s can be found at the Royal Navy Submarine Museum in Gosport, the Imperial War Museum in London, and the COMSUBIN Museum in La Spezia, Italy. The La Spezia craft remained in service until the late 1950’s, influencing the development of subsequent self-propelled underwater assault craft.

| Specifications |

The Siluro San Bartolomeo (SSB) stands as a superior evolution of the Siluro a Lenta Corsa (SLC), offering enhanced speed, range, manoeuvrability, and war load capacity. More than just an improvement in performance, the SSB represents a modernised design, marked by greater safety, reliability, and reduced susceptibility to mechanical and electrical failures. The technical data sheet by Caproni, the manufacturer responsible for its production shows the following characteristics.

The craft has an overall length of 6.77 meters, a maximum width of 0.79 meters, and a maximum depth of 1.08 meters. When fully prepared for operation, its total weight is 2,200 kilograms.

The hull is torpedo-shaped with a streamlined superstructure, optimised for minimal water resistance. At the centre, a free-circulation cockpit accommodates two operators seated in tandem. This configuration improves operator protection during high-speed navigation.

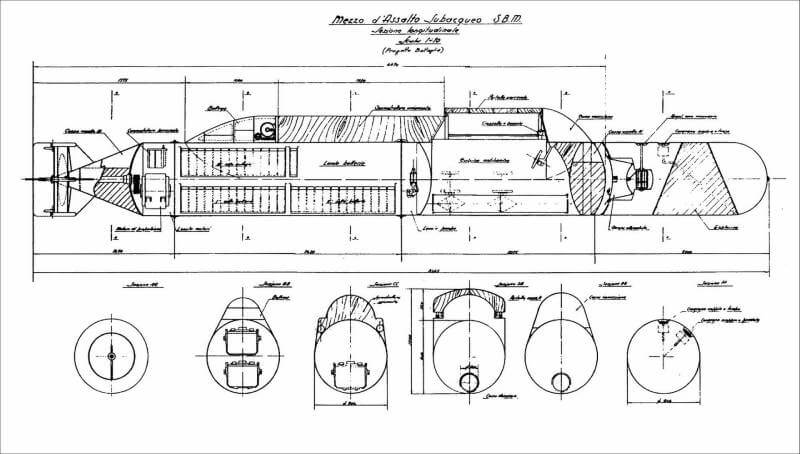

The craft is composed of four main sections:

- Warhead: Located at the bow, capable of housing various types of explosive payloads.

- Front Trim and Battery Compartment: Contains forward ballast tanks, accumulators, and control systems.

- Rear Trim and Battery Compartment: Balances the craft with aft ballast tanks and batteries.

- Propulsion Section: Houses the motor, trim pumps, rear ballast tanks, transmission, propellers, and rudders.

The armament configuration exists of:

- Standard Warhead: A semi-spherical explosive charge of 400 kilograms, affixed by a strap. Two radially positioned fuses provide detonation timing.

- Medium Warhead: Cylindrical and inserted between the standard warhead and the forward section, offering 300 kilograms of explosives for missions without length constraints.

- Short Dual Warheads: Divisible, each section carrying 180 kilograms of explosives. Designed for enhanced flexibility, each section is equipped with independent fuses.

The warheads exhibit slight negative buoyancy (1-2 kilograms) in water, maintaining nearly horizontal trim.

The propulsion system is driven by a 7.5-horsepower direct current motor, which transfers power through a gearbox to two counter-rotating, three-bladed propellers. This design enhances efficiency, cancels out propeller torque, and stabilizes the craft’s course. For series production, a patented motor without reduction gearing is proposed as a further improvement.

The motor operates at a voltage of 120 volts. Under maximum load, the motor draws a current of 70 amperes. It has a no-load rotational speed of 1,000 revolutions per minute and weighs 165 kilograms. The transmission system features a 2:1 ratio, effectively transferring power to the propellers.

The battery system comprises two compartments, each housing 30 cells, for a total of 60 cells. Each sub-battery has a capacity of 190 ampere-hours and operates at 60 volts. The weight of each sub-battery is 350 kilograms, ensuring a reliable and substantial energy supply for the motor. Battery compartments feature hatches for ventilation and recharging, enabling operations without disassembly.

Two ballast tanks manage buoyancy. The Forward Tank with a capacity of 90 litres and the Rear Tank with a capacity of 58 litres. Each tank is linked to an electric motor-driven gear pump. With the Control Levers, positioned on both sides of the cockpit, the right lever manages the stern and bow tanks, while the left controls the central trim tank.

In case of pump failure, a backup circuit permits water transfer between tanks using the alternate pump. Rapid surfacing and diving are managed by two high-pressure’rapid tanks, supported by 10 litres of air at 200 atmospheres, sufficient for over 15 surfacing manoeuvres.

The central cockpit features adjustable sheet-metal seats with footboards and knee pads. A steering yoke, positioned between the pilot’s legs, controls the rudders through a continuous steel cable system.

The non-magnetic dashboard includes a front-reading, spherical, watertight compass for navigation. An inclinometer displays the craft’s longitudinal trim. A depth gauge, made by SACMA in Milan, measures depths up to 30 meters. An ammeter monitors propulsion motor current from -20 to +140 amperes, while a voltmeter indicates supply voltage. A pump ammeter measures current up to 70 amperes. An air pressure gauge tracks surfacing tank pressure, and a water meter measures ballast water volume. All instruments are illuminated for night operations.

Under a hood aft of the rapid trim tank, additional equipment is stored, including a pneumatic net riser, net cutter, and cable shear with spare air cylinders. Four incendiary bombs are also stored for specific tasks. Two backup breathing apparatuses are available for emergencies. Service tools and spare parts are included for maintenance needs.

The aft compartment also contains battery control valves. Recharging occurs with the craft fully assembled, using a gas extraction system to ensure operator safety.

The Siluro San Bartolomeo includes a self-destruct mechanism activated by a time fuse, ensuring destruction in case of capture.

| Multimedia |

| Photographs |

| Construction |

| Testing by Allied |